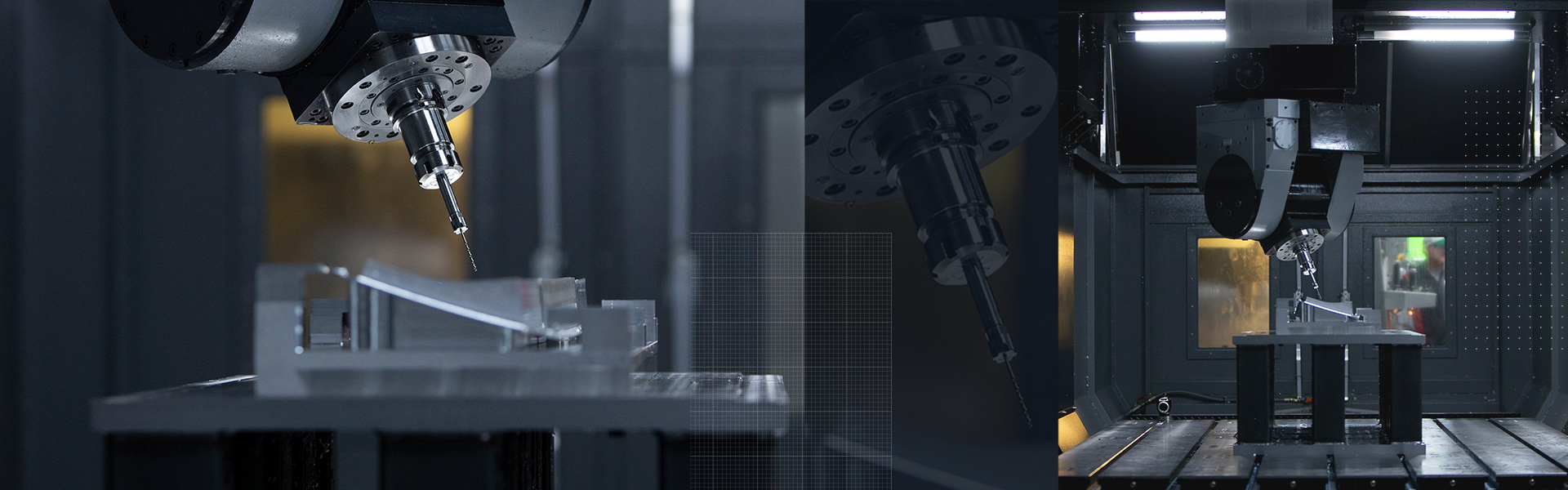

Precision CNC Manufacturing with 5-Axis Machining

As an experienced and professional machine shop specialized in CNC machining, McCay Tool and Engineering is capable of precision 5-axis CNC machining services and 5 axis-milling. When you are in need of high-quality and precise metal or plastic components, we can provide 5-axis machined aerospace parts that are complex, and meet the variety of needs required by the OEM.

Why Choose McCay’s 5-Axis CNC Machining Services

Since the aerospace industry continues to evolve, continuous reconfiguration and adaptation of parts are possible with 5-axis CNC machining. The setup for the machine enables complex geometries. At McCay, our process and quality control system are in place at every stage of our preparation, manufacturing, and inspection, to ensure the quality of 5-axis machined components consistently meets manufacturer requirements.

Benefits of 5-Axis Machining

- The 5-axis machining parts can be finished on a single 5 axis machine, which reduces fixture and setup preparation, saves a lot of time

- Complex geometries can be processed with ease; high productivity and efficiency can be guaranteed at the same time

- Excellent surface finishes can be achieved, improving the overall quality of parts

- Expanded capabilities, higher accuracy, boosted throughput, and shortened lead time

- Improved cutting conditions, maintaining the optimal cutting, and reducing damage to the tool

Key Aspects of 5-Axis Machining

- Capable of the same movements as 3-axis and 4-axis machine, with added rotation on X and Y axes.

- Typically, it is the bed that rotates rather than the tool head

- The added rotation allows for much more freedom when machining each setup

What is 5-Axis Machining?

The 3-, 4-, or 5-axis machining is defined related to the number of directions in which the cutting tool can move, this also determines the ability of a CNC machine to move a workpiece and a tool. 3-axis machines can move a component in X and Y directions and the tool moves up and down along Z-axis, while on the 5-axis machine, the tool can move across the X, Y and Z linear axes as well as rotate on the A and B axes, which means the cutter can approach the workpiece from any direction and any angle. 5- axis CNC machining services allow infinite possibilities of the machined parts.