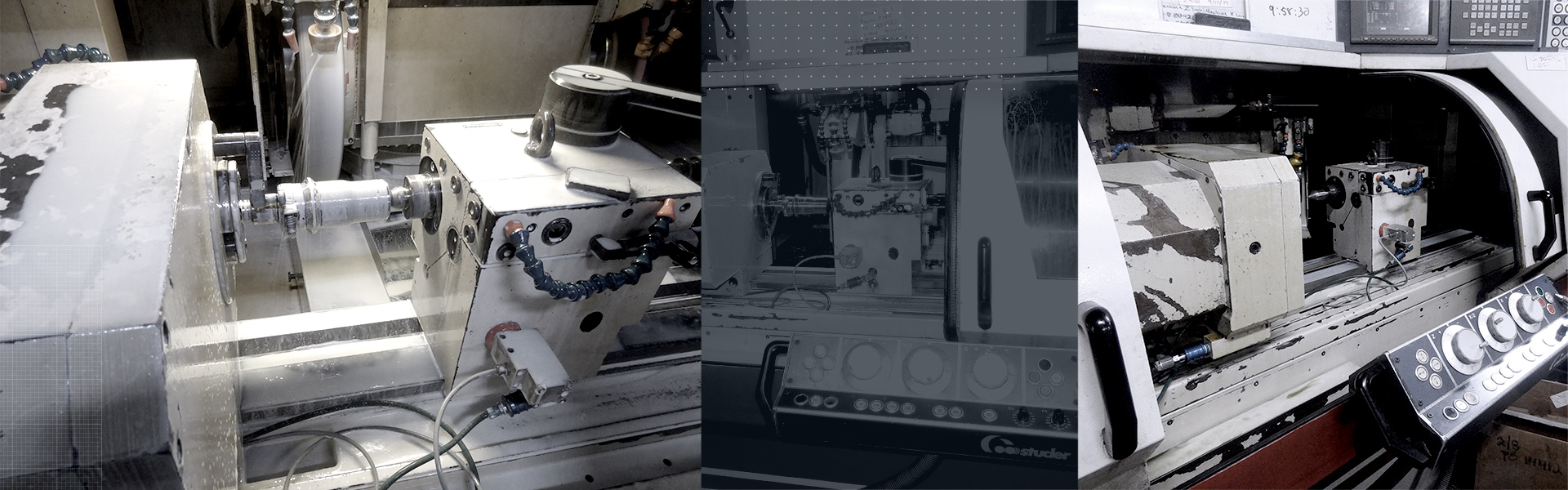

Cylindrical Grinding

Cylindrical grinding makes maximum precision in components possible. At McCay Tool and Engineering, we have state-of-the-art equipment to produce numerous components by using this complex grinding process. Cylindrical grinding is a vital component aerospace innovation therefore many of our products are created with a cylindrical grinder.

Our in-house deep grinding capabilities give us an advantage over our competitors in addressing your low-volume, high-mix component needs. We maintain more control over the finished product by grinding everything in one facility. Using our own sophisticated grinding equipment, our technicians produce some of the closest tolerances in the aerospace industry.

Whether nickel, hard-coated aluminum, or another alloy, materials for aerospace components must be temperature stable to withstand both the heat on the ground and the low temperatures in higher altitudes. However, these specialized materials can often prove challenging to machine, so aerospace component manufacturers often turn to cylindrical grinding, a technique that makes high-precision parts possible.

Our advanced and ongoing training for our technicians has allowed us to remain at the forefront of providing our clients with consistently reliable results and accurately ground components.

Cylindrical grinding is essential for aerospace manufacturing because it:

- Helps achieve the precision, temperature stability, rigidity, and vibration damping required for ultra-precise components

- Allows technicians to perform multiple operations in a single clamping to limit part handling that can compromise precision

- Enhances process repeatability and stability for more precise parts, from the first component to the last

Cylindrical grinding systems that fulfill these criteria are becoming vital for manufacturing highly accurate aerospace components. At McCay, our team of dedicated professionals is prepared to meet your project needs with exceptional quality, efficiency and design for ease of manufacturing.

Equipment in use:

You’ve come to expect tight tolerances and fine surface finishes across our full range of precision machining services including grinding.

Grinding:

- 3 Honing machines

- 2 Cylindrical Grinders

Why Cylindrical Grinding?

A cylindrical grinder is used to shape components of ranging sizes by removing material from the outside as the piece is rotated on an axis. The grinder can prepare cylinders in multiple shapes, not just straight pieces. The variety of tooling allows for a tapered cone, angled elements in different widths, and total shaped cylinders.