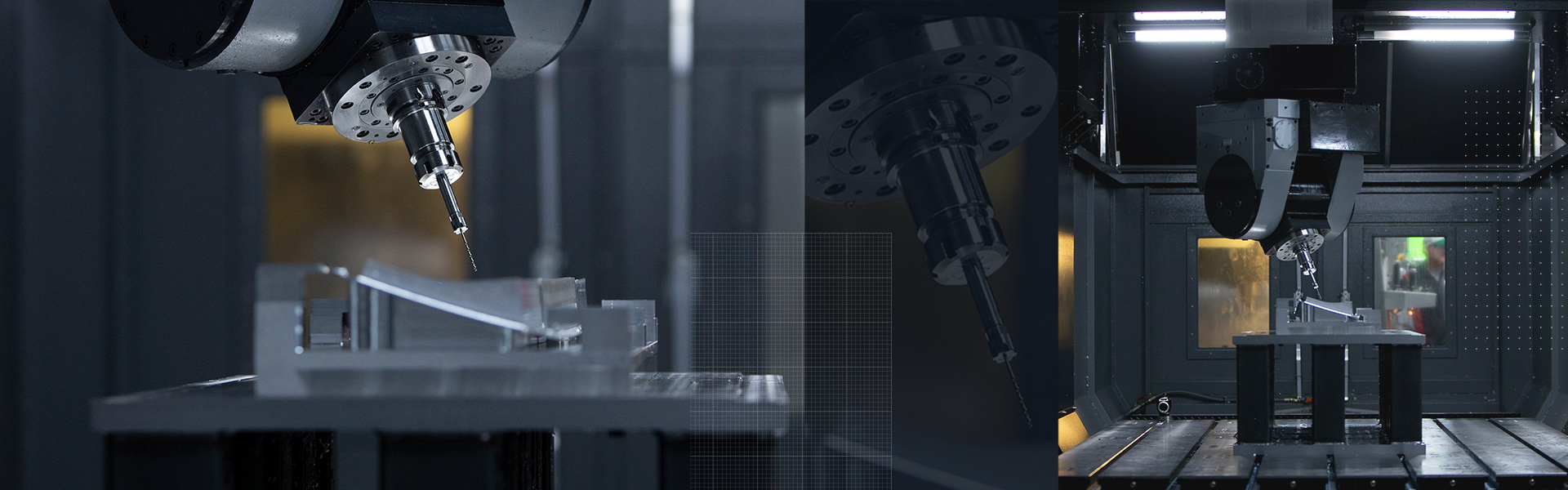

CNC Milling

Throughout our history, we’ve adapted and adhered to the latest in machining practices and technologies. Today, McCay Tool and Engineering is renowned as a leader in aerospace product machining. CNC Milling is only one of the CNC machining services we offer.

McCay offers state-of-the-art machinery including 5-axis milling equipment. Creating precision components with an outstanding surface finish is possible with our CNC milling service.

There are different types of milling tools to either mill axially, laterally or both ways. 5-axis CNC machines are the high standard and advanced type of CNC mill, which represents the manufacturing capabilities of CNC milling services. With this mill, we can machine 5 sides of a workpiece with one machine without multiple setups. Compared with 3-axis and 4-axis CNC milling, it is significantly more efficient and can be created geometrically complex parts with high accuracy.

Types of CNC Mills include:

- 3-Axis — these mills move the workpiece on X, Y, and Z axis, making them suitable for a wide variety of work.

- 4-Axis — for more continuous machining, 4-axis CNC mills add the vertical axis to rotate the machine.

- 5-Axis — in addition to the three traditional axes, 5-Axis CNC mills also have additional rotary axes, which allows for work on 5 sides of the workpiece and makes these machines more expensive to use.

Setting up the machine

Although CNC machines do the cutting work automatically, many other aspects of the process need a machine operator’s hand. Our experienced technicians bring years of experience in CNC milling and precise machining. Manual milling depends heavily on the operators while newer models have more advanced automation systems.

Our engineers and machinists can perform true 5-axis machining services and produce machined parts with ease. No matter how complex the CNC machining parts, each step will be executed with the highest quality standards

Equipment in Use:

- 5-Axis Mills

- 4 Trunnion Style full 5-axis capability; envelope of x=40, y=25, z=20

- 1 Gantry Style with full 5-axis spindle; envelope of x=120”, y=50,z=30

- 3- & 4-Axis Mills

- 15 Vertical Mills; envelope of x=64”, y=30, z=25”

- Horizontal Mills

- 1 12 pallet pool Horizontal Mill; envelope of x=32, y=39, z=25

Materials

We stock a variety of metal materials for various part applications. These include, but aren’t limited to:

- Aluminum

- Brass

- Bronze

- Copper

- Plastic

- Steel

- Titanium

- Zinc

What is CNC Milling?

CNC milling is a subtractive manufacturing method that uses a cutting tool to moves and rotate to remove material. CNC mills can be used for cutting and machining operations of various plastic and metal materials. It is suitable for any industry that requires precision components and is also an ideal tool for making molds.